Alloy Wire International

Datasheet: Haynes˘ 25 / L605

Haynes˘ 25 / L605

Haynes 25/L605 is a Cobalt-Nickel-Chromium-Tungsten alloy that combines good high temperature strength with good resistance to oxidising environments up to 980°C (1795°F) for long exposures. It also has excellent resistance to sulphidation, and responds extremely well to cold working. Known as the strongest of the formable Cobalt alloys, its widespread use has caused it to be investigated for use over a wide range of conditions, thus making it a well characterised material. Some of the industries Haynes 25/L605 is supplied to include aerospace, power generation, electronics, land-based turbines and medical.

Haynes 25/L605 is also known as Udimet L605.

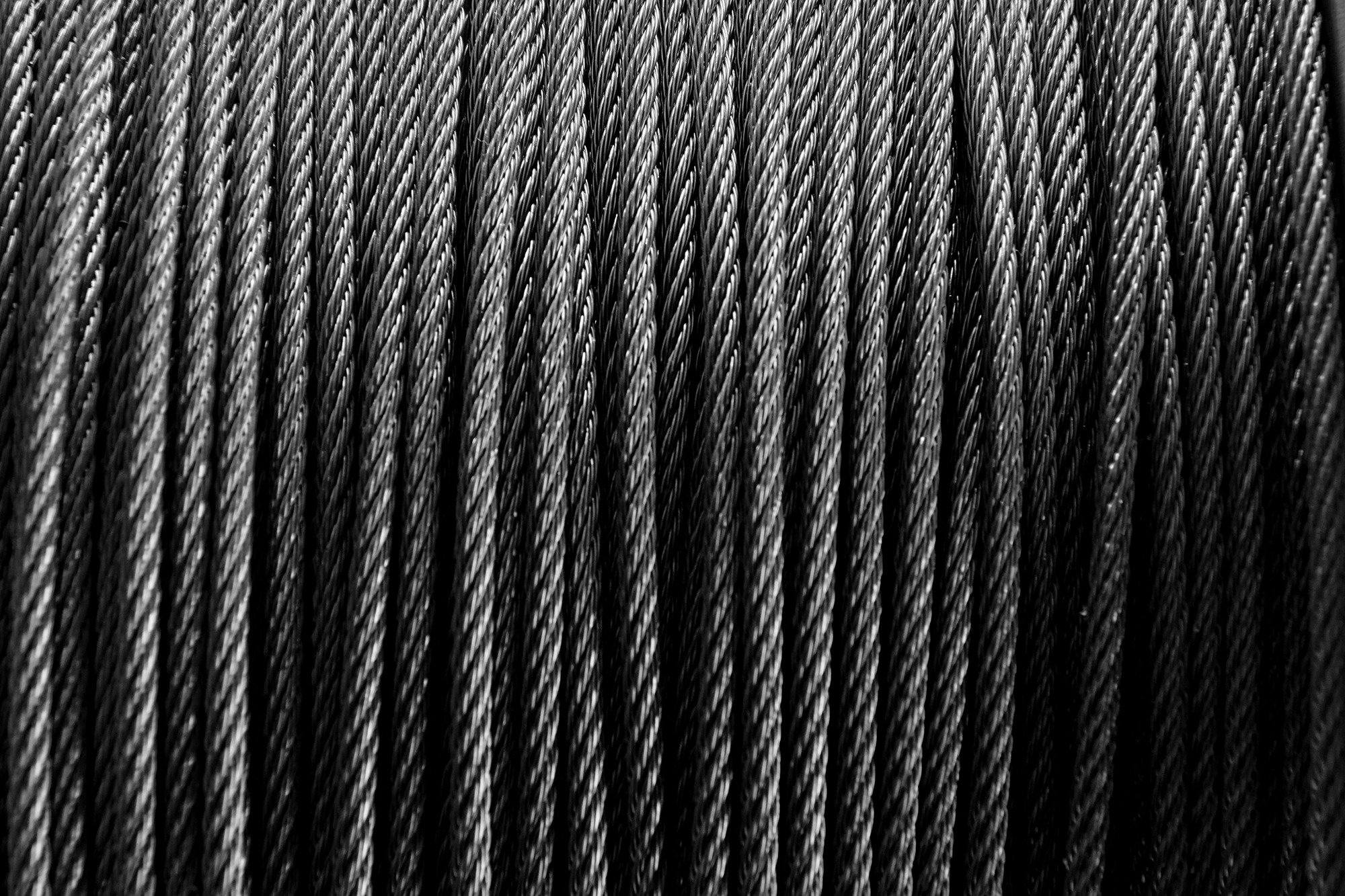

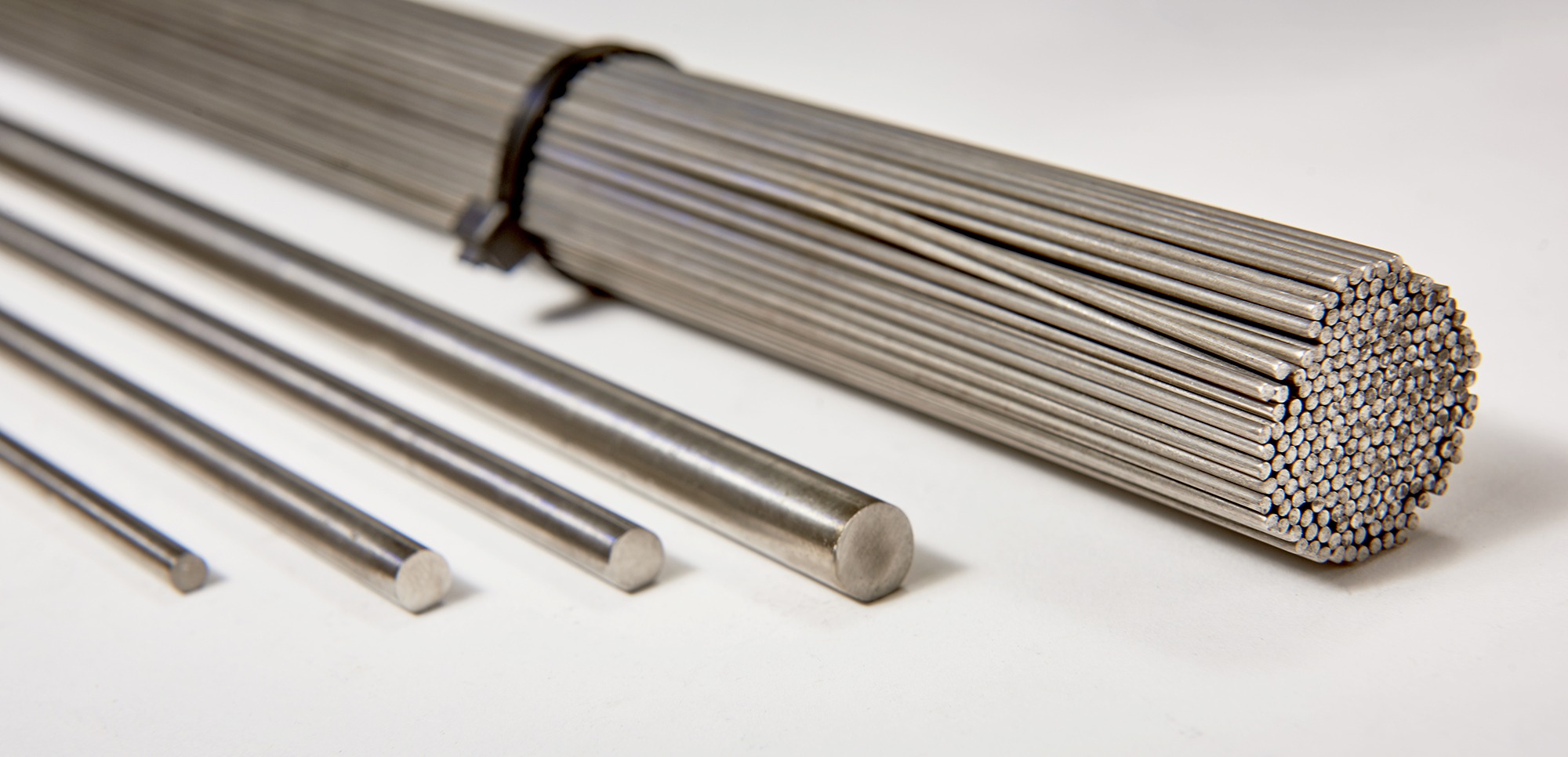

Available in all profile options

Key Features

Haynes 25/L605 offers the following key features:

Good resistance to oxidising environments at high temperatures for long exposures.

Excellent resistance to sulphidation.

High temperature static applications.**

Typical Applications

Haynes 25/L605 is known to be suitable for the following applications:

Designations

W.Nr 2.4964

UNS R30605

AWS 060

Specifications

AMS 5796

AMS 5759

ASTM F90

BS HR 40

ISO 15156-3

(NACE MR 0175)

Chemical Composition

The chemical composition of Haynes 25/L605 is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| C | 0.05 | 0.15 |

| Mn | 1.00 | 2.00 |

| Si | – | 0.40 |

| P | – | 0.04 |

| S | – | 0.03 |

| Cr | 19.00 | 21.00 |

| Ni | 9.00 | 11.00 |

| W | 14.00 | 16.00 |

| Fe | – | 3.00 |

| Co | bal |

Alloy Details

Haynes 25/L605 density, melting point, coefficient of expansion, and modulus of elasticity is indicated in the table below:

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 9.13 g/cm³ | 1410 °C | 12.3 μm/m °C (20 – 100 °C) | 98 kN/mm² | 225 kN/mm² |

| 0.330 lb/in³ | 2570 °F | 6.8 x 10-6 in/in °F (70 – 212 °F) | 14214 ksi | 32634 ksi |

Heat treatment of finished parts

The typical heat treatment of Haynes 25/L605:

| Condition as supplied by AWI | Type | Temperature | Time | Cooling |

|---|---|---|---|---|

| Annealed or Spring Temper | Stress Relieve | 400 – 450 °C (750 – 840 °F) | 2 Hr | Air |

Properties

The typical mechanical properties of Haynes 25/L605:

| Annealed | ||

|---|---|---|

| Approx. tensile strength | 900 – 1500 N/mm² | 131 – 218 ksi |

| Approx. operating temperature depending on load** and environment | -200 to +900 °C | -330 to +900 °F |

| Spring Temper | ||

|---|---|---|

| Approx. tensile strength | 1400 – 1800 N/mm² | 203 – 261 ksi |

| Approx. operating temperature depending on load** and environment | -200 to +900 °C | -330 to +1650 °F |

The above tensile strength ranges are typical. If you require different please ask.

* Trade name of Haynes International ** Static applications = still/fixed/motionless/rigid