Alloy Wire International

Datasheet: Inconel® 625

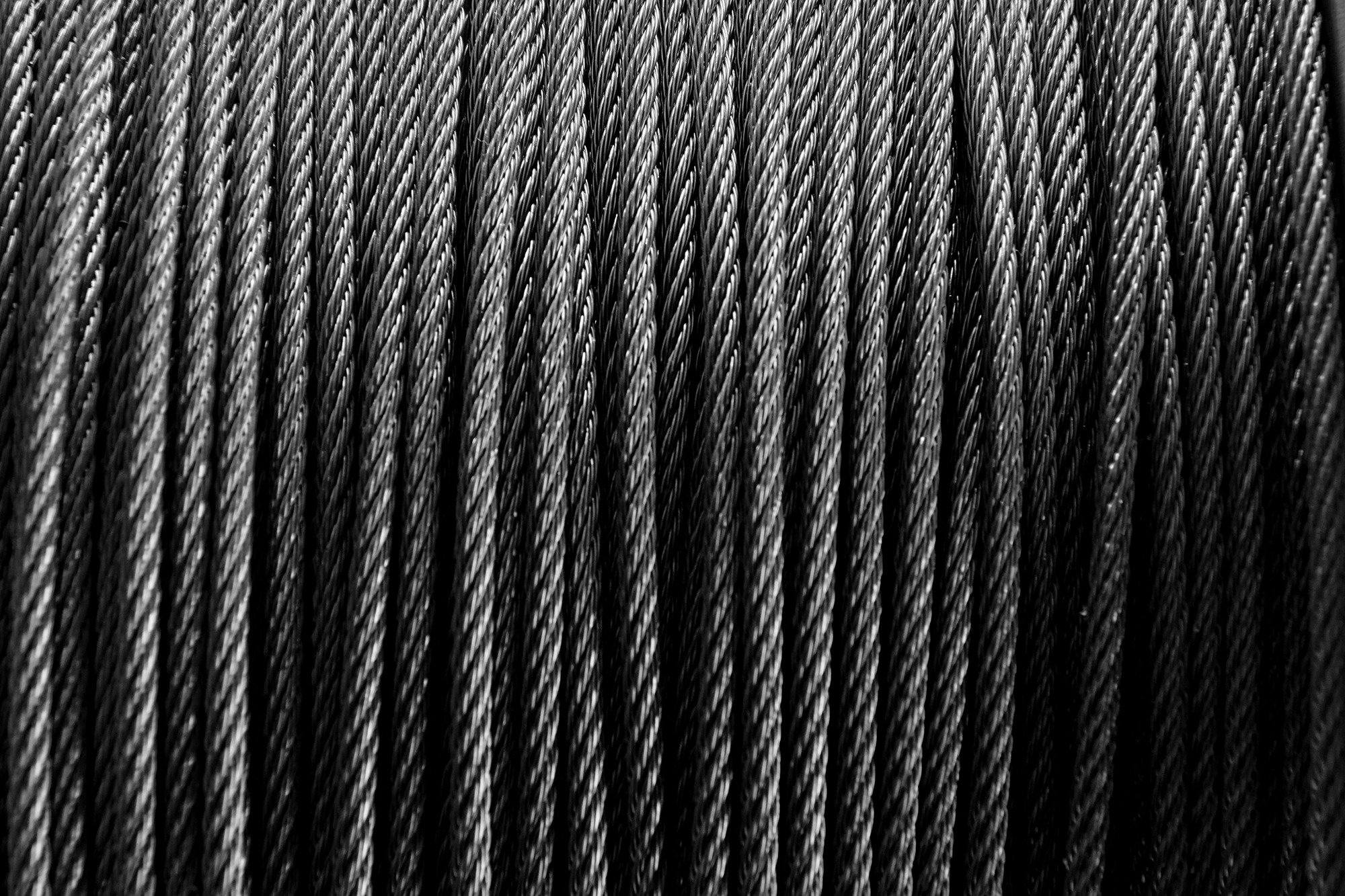

Inconel® 625

A Nickel-Chromium-Molybdenum alloy with excellent corrosion resistance in a wide range of corrosive media, being especially resistant to pitting and crevice corrosion. Inconel® 625 provides resistance to stress corrosion cracking to chloride ions, making it a favourable choice for sea water applications. The alloy also provides commendable oxidation resistance, with its high strength a result of the stiffening combination of Molybdenum and Niobium on the alloy’s Nickel-Chromium base.

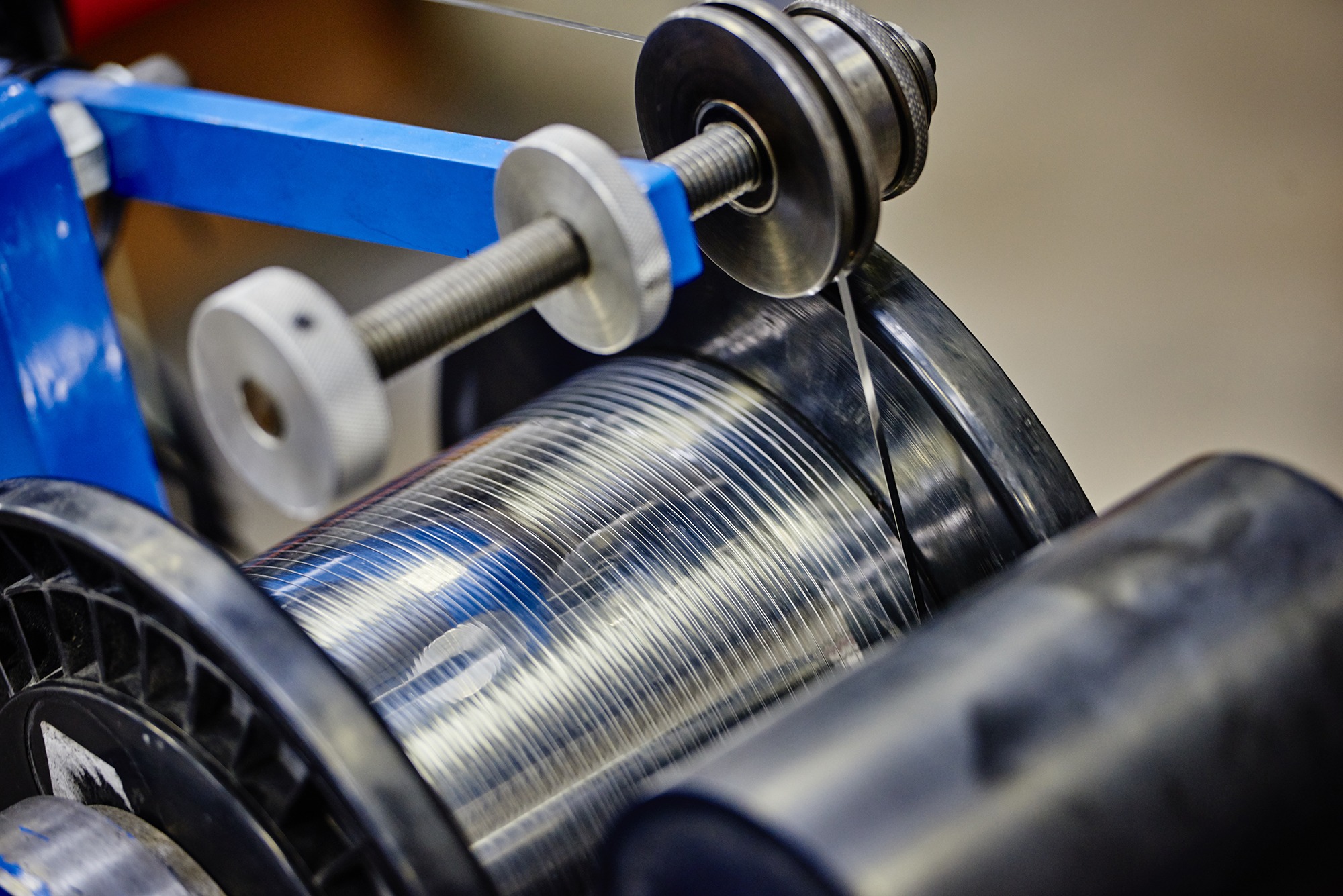

Available in all profile options

Key Features

Inconel® 625 offers the following key features:

Excellent corrosion resistance in a wide range of corrosive media

Especially resistant to pitting and crevice corrosion

Good for sea water applications

Typical Applications

Inconel® 625 is known to be suitable for the following applications:

Marine Industries

Aerospace Industries

Chemical Processing

Nuclear Reactors

Pollution Control

Designations

W.NR 2.4856

UNS N06625

AWS 012

Specifications

AMS 5666

ASTM B446

BS 3076 NA 21

ISO 15156-3

(NACE MR 0175)

Chemical Composition

The chemical composition of Inconel® 625 is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| C | – | 0.10 |

| Mn | – | 0.50 |

| Si | – | 0.50 |

| P | – | 0.015 |

| S | – | 0.015 |

| Cr | 20.00 | 23.00 |

| Co | – | 1.00 |

| Mo | 8.00 | 10.00 |

| Fe | – | 5.00 |

| Al | – | 0.40 |

| Ti | – | 0.40 |

| Ni | 58.00 | – |

| Nb/Cb | 3.15 | 4.15 |

| Ta | – | 0.05 |

| Cu | – | 0.5 |

Alloy Details

Inconel® 625 density, melting point, coefficient of expansion, modulus of rigidity, and elasticity is indicated in the table below:

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 8.44 g/cm³ | 1350 °C | 12.8 μm/m °C (20 – 100 °C) | 79 kN/mm² | 205.8 kN/mm² |

| 0.305 lb/in³ | 2460 °F | 7.1 x 10-6 in/in °F (70 – 212 °F) | 11458 ksi | 29849 ksi |

Heat treatment of finished parts

The typical heat treatment of Inconel® 625:

| Condition as supplied by AWI | Type | Temperature | Time | Cooling |

|---|---|---|---|---|

| Annealed or Spring Temper | Stress Relieve | 260 – 370°C (500 – 700°F) | 0.5 – 1hr | Air |

Properties

The typical mechanical properties of Inconel® 625:

| Annealed | ||

|---|---|---|

| Approx. tensile strength | < 1050 N/mm² | < 152 ksi |

| Approx. operating temperature | -200 to +340 °C | -330 to +645 °F |

| Spring Temper | ||

|---|---|---|

| Approx. tensile strength | 1300 – 1600 N/mm² | 189 – 232 ksi |

| Approx. operating temperature | up to +200 °C | up to +395 °F |

The above tensile strength ranges are typical. If you require different please ask.

*Trade name of Special Metals Group of Companies