Alloy Wire International

Datasheet: Incoloy® 825

Incoloy® 825

Incoloy® 825 is a Nickel-Iron-Chromium alloy with additions of Molybdenum and Copper. It has excellent resistance to both reducing and oxidising acids, to stress-corrosion cracking and to localised pitting. It is also especially resistant to sulphuric and phosphoric acids. Alongside Inconel® 625, Incoloy® 825 is one of the most important nickel alloys for the oil and gas industry. Thanks to the balance of elements, it offers exceptional resistance to chloride stress corrosion cracking, as well as crevice corrosion and general corrosion.

Incoloy® 825 is also known as Nicrofer 4221, Superimphy 82 and Ferrochronin 825.

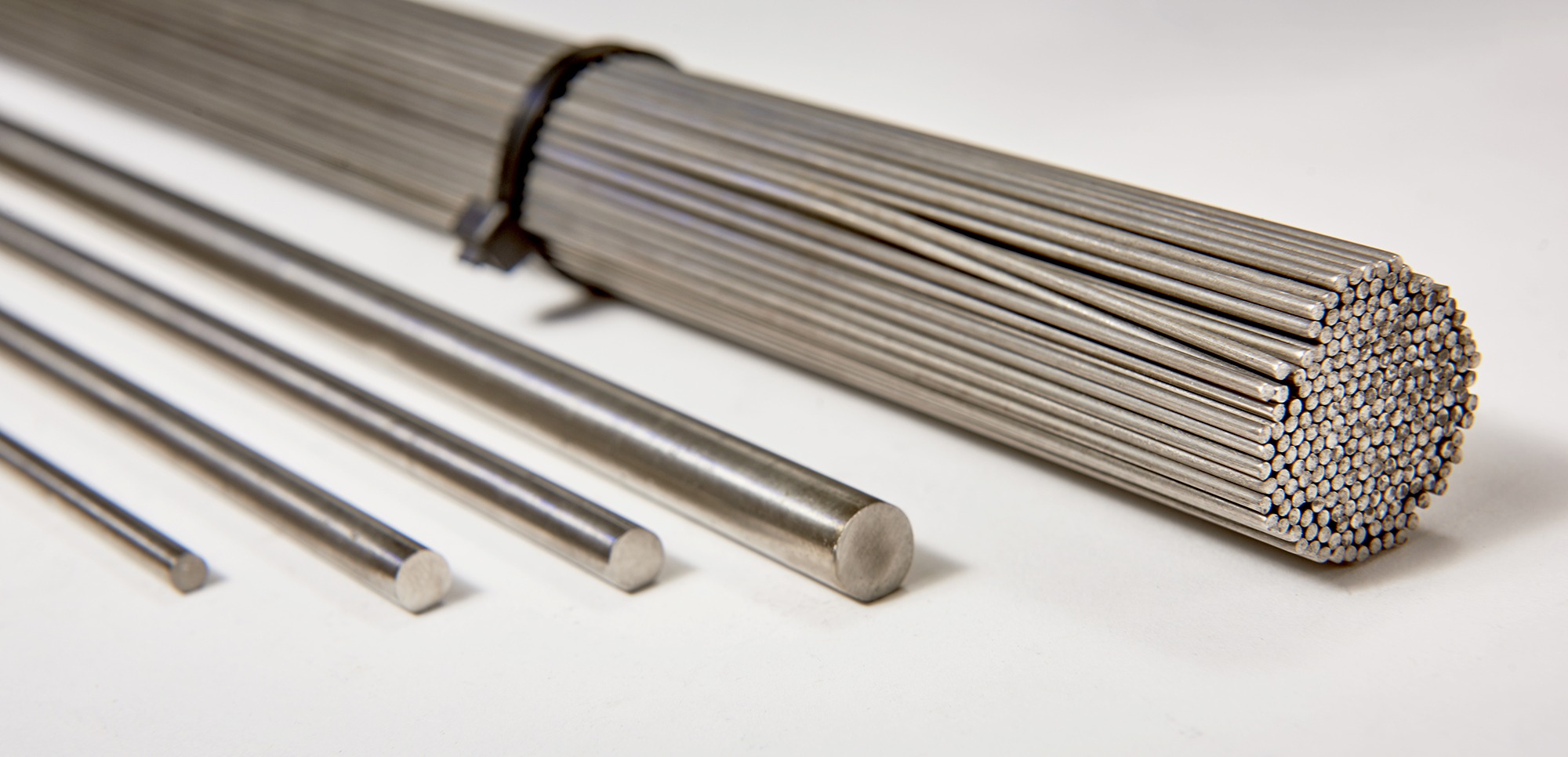

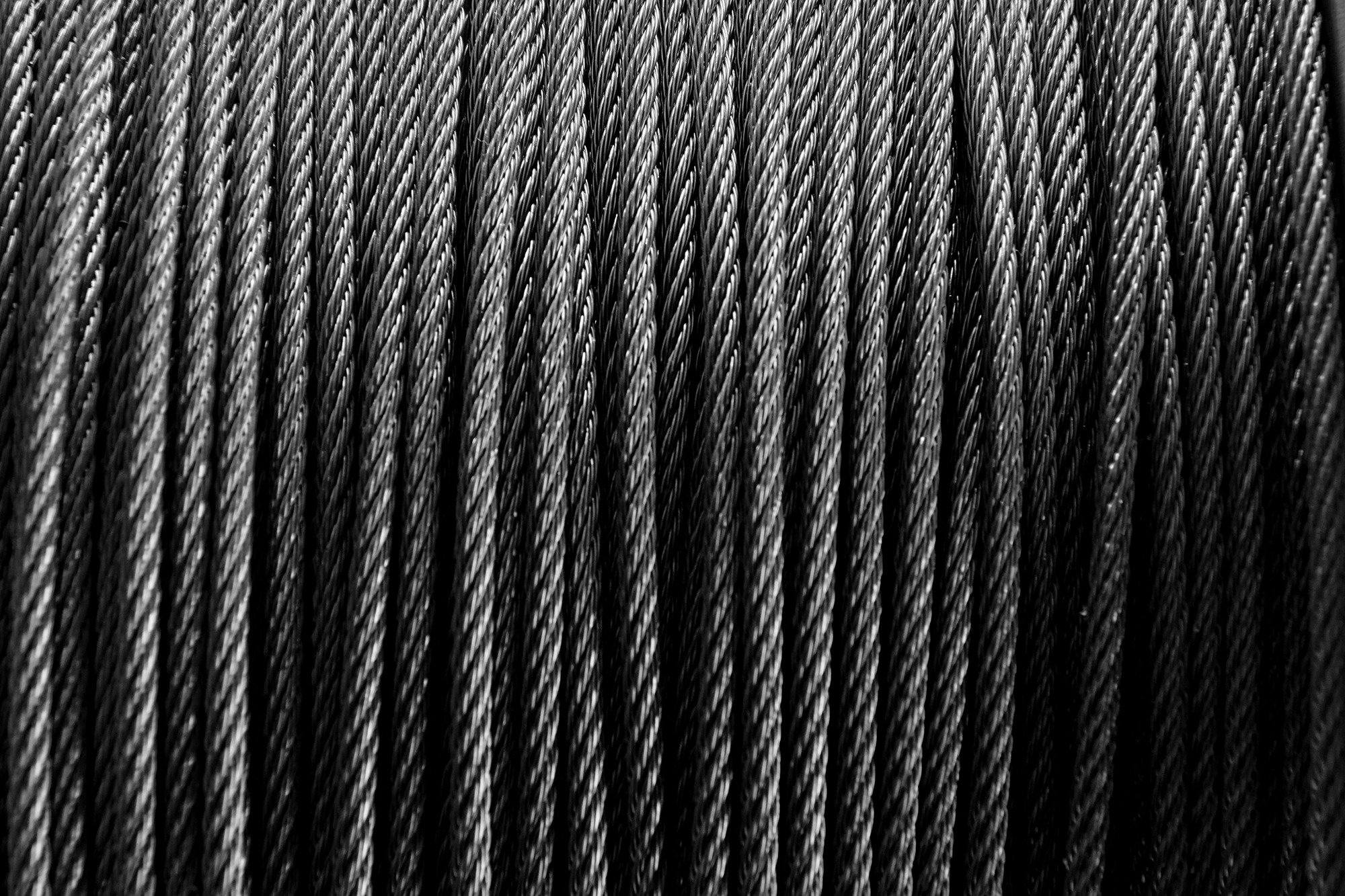

Available in all profile options

Key Features

Incoloy® 825 offers the following key features:

Resistant to reducing environments such as those containing sulphuric and phosphoric acids

Resistant to a variety of oxidising substances such as nitric acid and nitrates

Resistant to chloride-ion stress corrosion cracking and, pitting & crevice corrosion

Good for chemical processing

Typical Applications

Incoloy® 825 is known to be suitable for the following applications:

Chemical Processing

Nuclear Fuel Reprocessing

Acid Production

Pickling Equipment

Designations

W.Nr 2.4858

UNS N08825

AWS 022

Specifications

ASTM B425

BS 3075 NA 16

BS 3076 NA 16

ISO 15156-3

(NACE MR 0175)

Chemical Composition

The chemical composition of Incoloy® 825 is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| Ni | 38.00 | 46.00 |

| Co | – | 2.00 |

| Cu | 1.50 | 3.00 |

| Cr | 19.50 | 23.50 |

| Mo | 2.50 | 3.50 |

| Al | – | 0.20 |

| C | – | 0.05 |

| Si | – | 0.50 |

| Mn | – | 1.00 |

| S | – | 0.03 |

| Ti | 0.60 | 1.20 |

| Fe | Bal |

Alloy Details

Incoloy® 825 density, melting point, coefficient of expansion, and modulus of elasticity is indicated in the table below:

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 8.14 g/cm³ | 1400 °C | 14.0 μm/m °C (20 – 100 °C) | 75.9 kN/mm² | 196 kN/mm² |

| 0.294 lb/in³ | 2550 °F | 7.8 x 10-6 in/in °F (70 – 212 °F) | 11009 ksi | 28428 ksi |

Heat treatment of finished parts

The typical heat treatment of Incoloy® 825:

| Condition as supplied by AWI | Type | Temperature | Time | Cooling |

|---|---|---|---|---|

| Annealed or Spring Temper | Stress Relieve | 450 – 470 °C (840 – 880 °F) | 0.5 – 1 Hr | Air |

Properties

The typical mechanical properties of Incoloy® 825:

| Annealed | ||

|---|---|---|

| Approx. tensile strength | <800 N/mm² | <116 ksi |

| Approx. operating temperature depending on load** and environment | -100 to +250 °C | -145 to +480 °F |

| Spring Temper | ||

|---|---|---|

| Approx. tensile strength | 800 – 1100 N/mm² | 116 – 159 ksi |

| Approx. operating temperature depending on load** and environment | -100 to +250 °C | -145 to +480 °F |

The above tensile strength ranges are typical. If you require different please ask.

*Trade name of Special Metals Group of Companies