Alloy Wire International

Datasheet: Rene 41

Rene 41

Rene 41 is an age hardenable nickel base alloy that has very high strength at elevated temperatures, particularly within the range of 650 – 980 °C (1200 – 1800 °F).

Required mechanical properties can be tailored by selection of various combinations of cold work and/or heat treatments. Rene 41 also has good oxidation resistance.

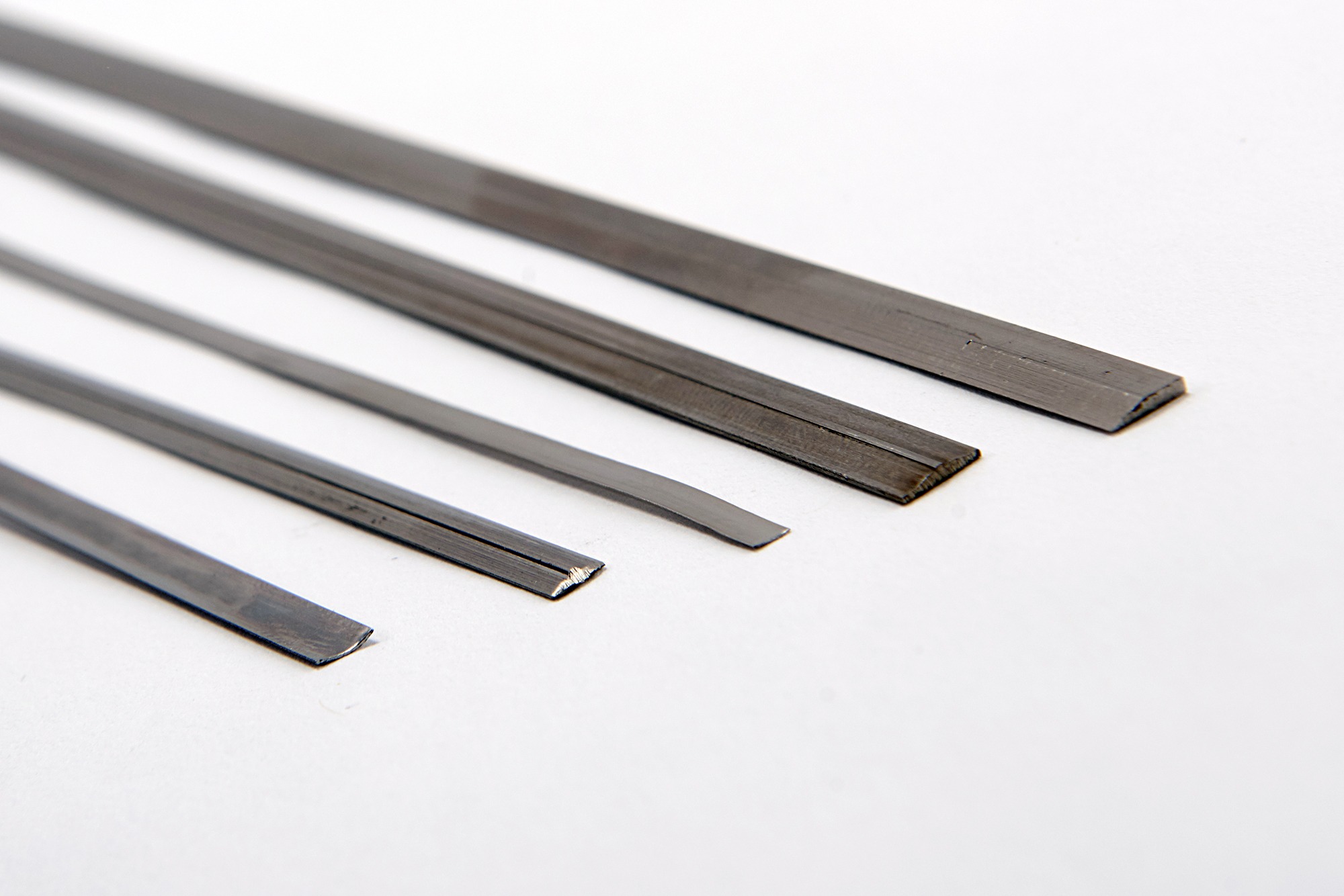

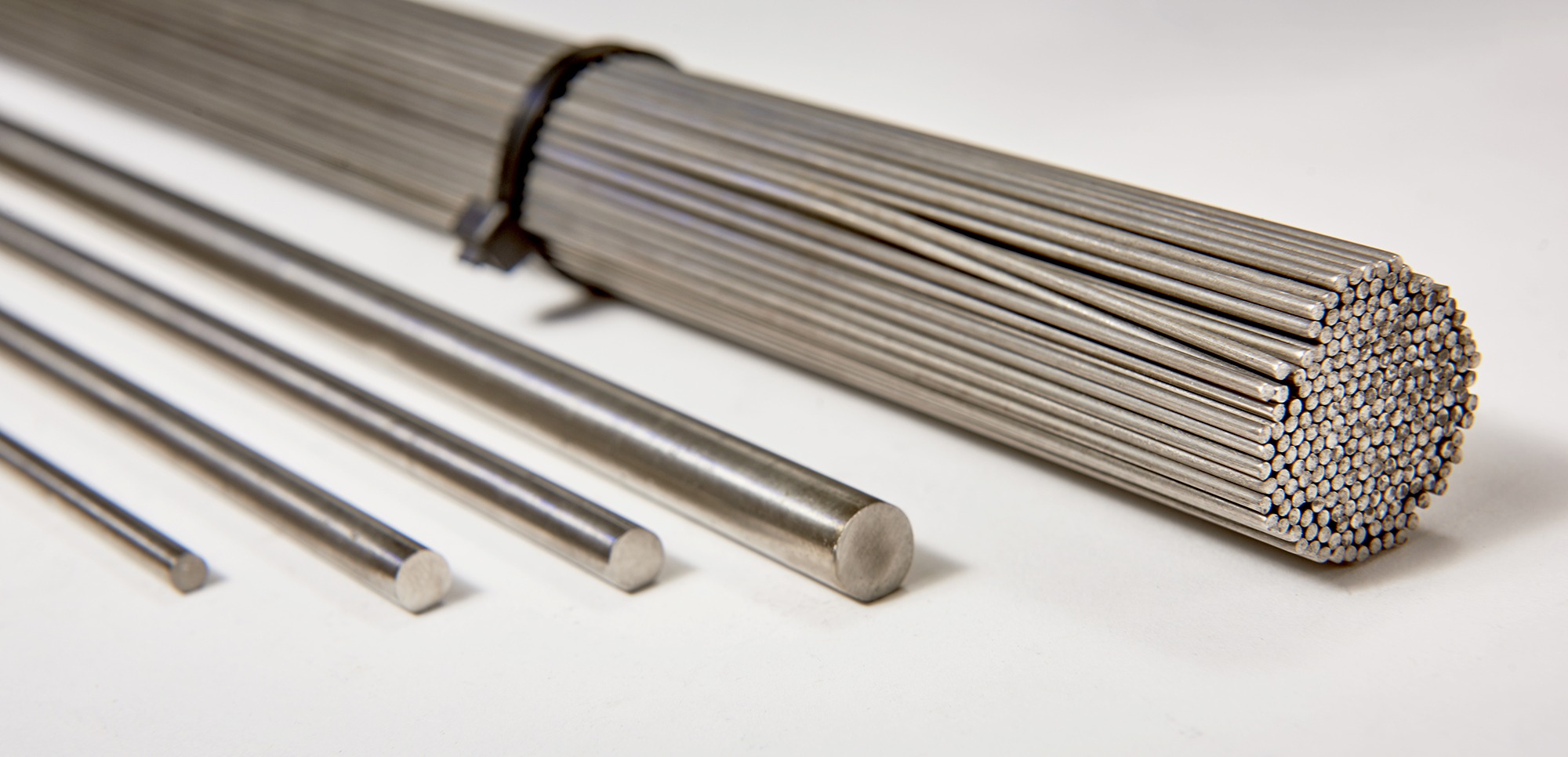

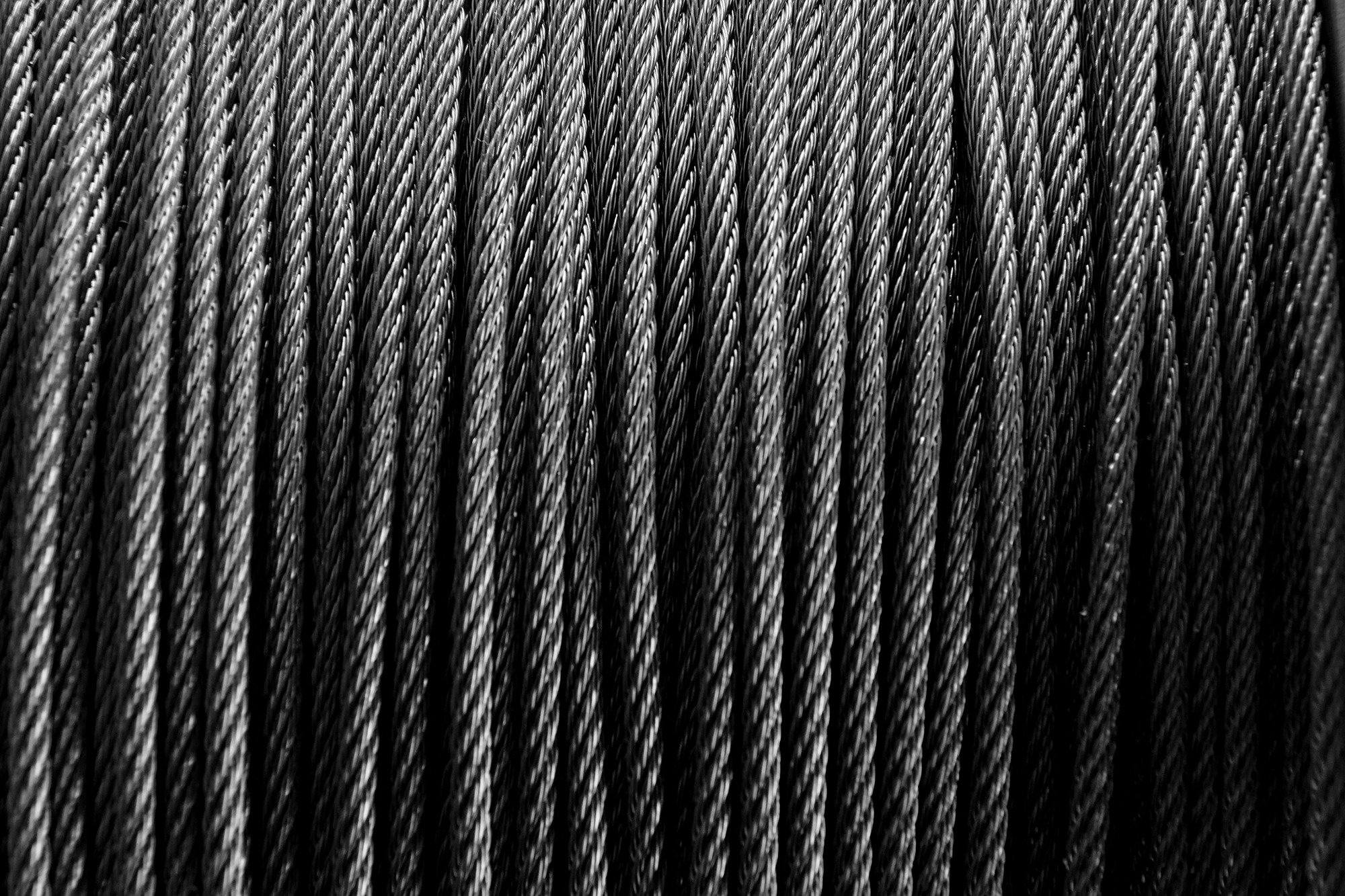

Available in all profile options

Key Features

Rene 41 offers the following key features:

Very high strength at elevated temperatures.

Good oxidation resistance.

Age hardenable.

High temperature dynamic applications.^^

Typical Applications

Rene 41 is known to be suitable for the following applications:

After burner parts

Turbine castings

Bolts

Other fasteners

Designations

W.Nr 2.4973

UNS N07041

AWS 120

Specifications

AMS 5545

AMS 5713

AMS 5800

AMS 5712

GE C50T71

Chemical Composition

The chemical composition of Rene 41 is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| C | – | 0.12 |

| Mn | – | 0.10 |

| Si | – | 0.50 |

| S | – | 0.015 |

| Cr | 18.00 | 20.00 |

| Co | 10.00 | 12.00 |

| Mo | 9.00 | 10.50 |

| Ti | 3.00 | 3.30 |

| Al | 1.40 | 1.60 |

| B | 0.003 | 0.01 |

| Fe | – | 5.00 |

| Ni | bal |

Alloy Details

Rene 41 density, melting point, coefficient of expansion, and modulus of elasticity is indicated in the table below:

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 8.25 g/cm³ | 1345 °C | 13.6 μm/m °C (20 – 100 °C) | 83.2 kN/mm² | 218.0 kN/mm² |

| 0.298 lb/in³ | 2450 °F | 7.41 x 10-6 in/in °F (70 – 212 °F) | 12067 ksi | 31619 ksi |

Heat treatment of finished parts

The typical heat treatment of Rene 41:

| Condition as supplied by AWI | Type | Temperature | Time | Cooling |

|---|---|---|---|---|

| Annealed | Age Harden | 760 °C (1400 °F) | 16 Hr | Air |

| Spring Temper | Solution Anneal Age Harden | 1065 °C (1950 °F) 760 °C (1400 °F) | 4 Hr 16 Hr | Air Air |

Properties

The typical heat treatment of Rene 41:

| Annealed | ||

|---|---|---|

| Approx. tensile strength | <1100 N/mm² | <159 ksi |

| Approx. operating temperature depending on load^^ and environment | – | – |

| Annealed + Aged | ||

|---|---|---|

| Approx. tensile strength | 1350 – 1550 N/mm² | 196 – 225 ksi |

| Approx. operating temperature depending on load^^ and environment | up to +550 °C | up to +1020 °F |

| Spring Temper | ||

|---|---|---|

| Approx. tensile strength | 1400 – 1800 N/mm² | 203 – 261 ksi |

| Approx. operating temperature depending on load^^ and environment | – | – |

| Spring Temper + Annealed + Aged | ||

|---|---|---|

| Approx. tensile strength | 1350 – 1550 N/mm² | 196 – 225 ksi |

| Approx. operating temperature depending on load^^ and environment | up to +550 °C | up to +1020 °F |

| Spring Temper + Aged | ||

|---|---|---|

| Approx. tensile strength | 1600 – 2000 N/mm² | 232 – 290 ksi |

| Approx. operating temperature depending on load^^ and environment | up to +550 °C | up to +1020 °F |

The above tensile strength ranges are typical. If you require different please ask.

*Trade name of General Electric Inc.

^^ Dynamic applications = active / lively / changing