Alloy Wire International

Datasheet: Phynox†

Phynox†

This Cobalt-Chromium-Nickel alloy gives a combination of high strength, ductility and good mechanical properties and is age hardenable. Phynox† also has excellent fatigue life, corrosion resistance in numerous environments and is non-magnetic.

Phynox† often provides the ideal solution whenever high mechanical performance is required under severely corrosive service conditions. Its mechanical strength increases with cold rolling strain, while additional strengthening can be achieved by age hardening at 520°C.

It is recommended to use Phynox† where a high resistance to corrosion and / or low relaxation at temperatures up to 380°C (715°F) are required. This alloy is used in medical devices, dental products, surgical implants and orthopedics.

Phynox† is also known as Elgiloy, Conichrome and Alloy 3J21.

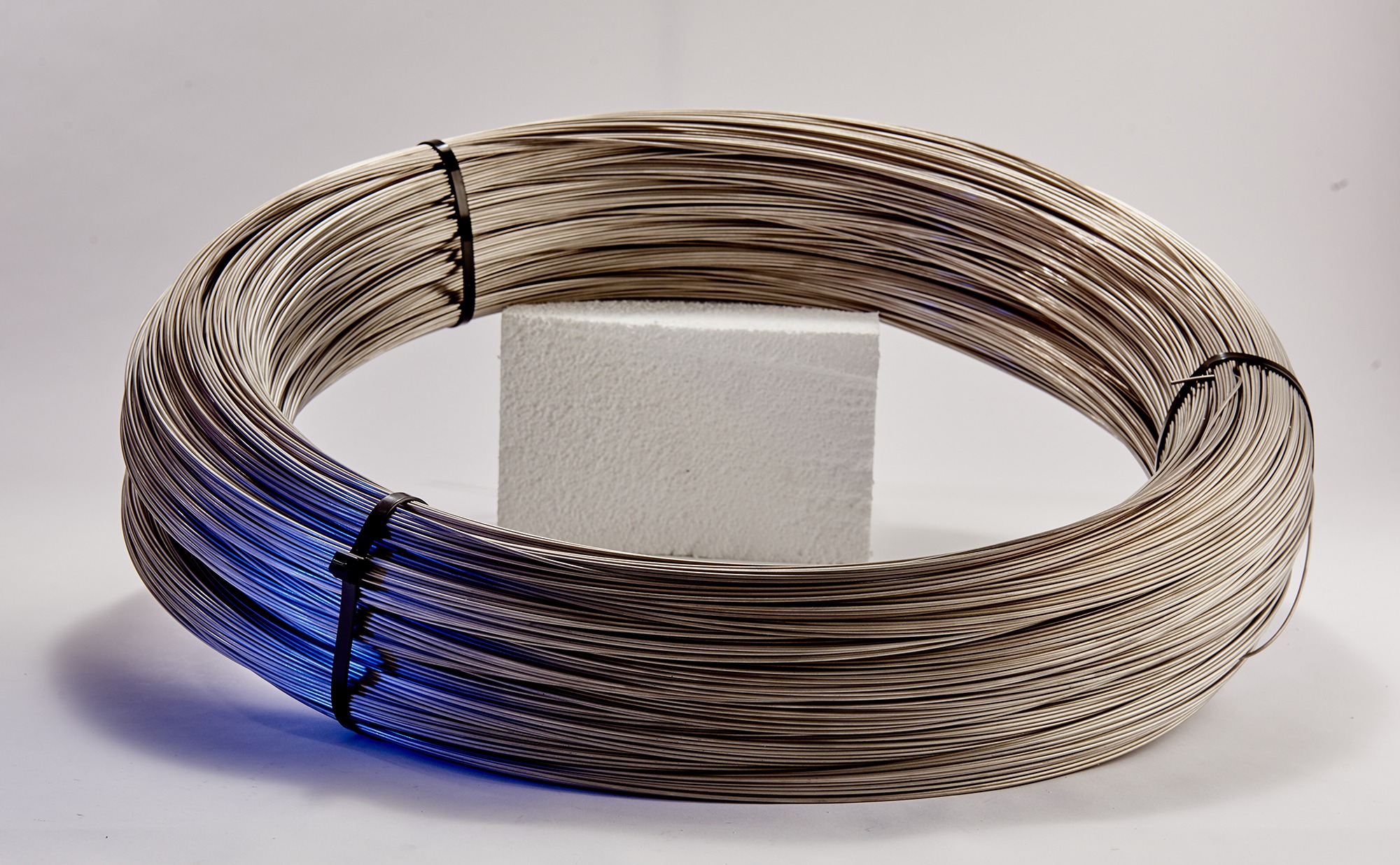

Available in all profile options

Key Features

Phynox offers the following key features:

Combination of high strength, ductility and good mechanical properties at ambient temperatures.

Excellent fatigue life.

Excellent corrosion resistance in numerous environments.

Non magnetic.

Age hardenable (Spring Temper only).

Good for sea water applications.

Typical Applications

Phynox is known to be suitable for the following applications:

Springs

Seal components

Medical devices

Components for watches

Aerospace applications

Petrochemical applications

Marine engineering

Designations

W.Nr 2.4711

UNS R30003

UNS R30008

AWS 100

Specifications

AMS 5833

AMS 5834

AMS 5876

ASTM F1058

ISO 5832-7

ISO 15156-3

(NACE MR 0175)

Chemical Composition

The chemical composition of Phynox is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| C | – | 0.15 |

| Mn | 1.50 | 2.50 |

| Si | – | 1.20 |

| P | – | 0.015 |

| S | – | 0.015 |

| Cr | 19.00 | 21.00 |

| Ni | 14.00 | 16.00 |

| Co | 39.00 | 41.00 |

| Mo | 6.00 | 8.00 |

| Be | – | 0.10 |

| Fe | bal |

Alloy Details

Phynox density, melting point, coefficient of expansion, and modulus of elasticity is indicated in the table below:

| Dennsity | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 8.3 g/cm³ | 1427 °C | 12.5 μm/m °C (20 – 100 °C) | 77 kN/mm² | 203.4 kN/mm² |

| 0.300 lb/in³ | 2600 °F | 7.0 x 10-6 in/in °F (70 – 212 °F) | 11168 ksi | 29501 ksi |

Heat treatment of finished parts

The typical heat treatment of Phynox:

| Condition as supplied by AWI | Type | Temperature | Time | Cooling |

|---|---|---|---|---|

| Annealed | – | – | – | – |

| Spring Temper | Age Harden | 520 °C (970 °F) | 5 Hr | Air |

Properties

The typical mechanical properties of Phynox:

| Annealed | ||

|---|---|---|

| Approx. tensile strength | < 1100 N/mm² | < 160 ksi |

| Approx. operating temperature depending on load** and environment | -185 to +450 °C | -300 to +840 °F |

| Spring Temper | ||

|---|---|---|

| Approx. tensile strength | 1400 – 1900 N/mm² | 203 – 276 ksi |

| Approx. operating temperature depending on load** and environment | -185 to +450 °C | -300 to +840 °F |

| Spring Temper + Aged | ||

|---|---|---|

| Approx. tensile strength | 1900 – 2200 N/mm² | 276 – 319 ksi |

| Approx. operating temperature depending on load** and environment | -185 to +450 °C | -300 to +840 °F |

The above tensile strength ranges are typical. If you require different please ask.

† Trade Name registered to Aperam Alloys Imphy